Dear X.Y.,

many thanks for your reply.

I am sorry that my information was not detailed enough to explain what I want to do and what for.

Let us give it a second try, I will do my best to be more accurate.

Q1: I do NOT want to touch the frame TUBES of the Strida, no more ore bigger holes in any way.

Actually I meant drilling a hole (diameter less than 7,5 mm) into the PLASTIC material of the SEAT MOLDING.

Placed in the correct position (marked red in the attached paper drawings to be seen on pics QRSmod 01-03.jpg) , this hole will make the change of a (modified) seat pin from upper to lower position possible without the need of unmounting the complete seat molding (and the saddle) to change the positions of the seat pin!

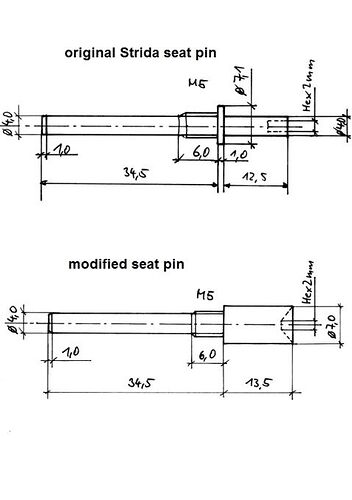

[For better understanding please refer to picture seat pin 03.jpg, the drawing shows the original Strida and the modified seat pin. The modified pin contains a little magnet, which provides enough force to hold the 2mm Allen key safely for inserting the seat pin to the desired (upper or lower) hole of the rear tube THROUGH the plastic part of the seat molding. Here I have to notice that another little modification relating to the part QR locking mount.jpg is implicitly necessary. Of course the hole in the locking mount must have the same diameter as the one in the seat molding! As the modified seat pin has a diameter of 7,0mm, the hole must be 7,5mm, I mean.]

Here the desired function of the Strida QRS in steps, for example changing from upper to lower position of the seat pin:

- open top and bottom Q/R lever

- pull Q/R locking lever

- slide seat molding in position with hole over seat pin, release Q/R locking lever

- retract seat pin from upper position with 2mm Allen key (THROUGH the seat molding)

- slightly pull Q/R locking lever and

- slide complete seat molding with locking mount and locking lever to lower postion, hole in the seat molding over lower hole for seat pin, release Q/R locking lever

- insert the (magnetic) seat pin with 2mm Allen key and make sure the locking lever fits onto the seat pin

- lock top and bottom Q/R lever

Now the seat pin has changed its position from upper to lower WITHOUT un- and remounting of saddle and QRS.

There is no need to carry two 13mm wrenches with you, the time saving is enormous.

The question newly phrased, logically similar:

The top and bottom Q/R lever clamps MUST transfer the FULL weight force of the rider to the frame.

The seat pin and the Q/R locking lever mechanics MUST NOT transfer ANY weight force of the rider to the frame.

Is that correct?

Q2: The nut of the saddle bolt is marked A2-70, this is without any doubt STAINLESS STEEL!

The saddle bolt is made of DIFFERENT MATERIAL, which is marked KSFC M.

A simple test verifies the DIFFERENT materials: The BOLT IS magnetic, the NUT IS NOT!

Please refer to attached picture saddle bolt 01.jpg to see the markings.

Please refer to “A2-70” here:

volksbolts.com/faq/basics.htm

or here:

kqfastener.en.made-in-china.com/ … A2-70.html

bssa.org.uk/publications.php?id=42

or just google “A2-70”

Please talk to your technicians, they must know about “A2-70”!

And, partially, you are right, stainless steel contains chromium and molybdenum in various amounts as an alloying component.

However, the use of stainless steel, in combination with stainless steel OR non-stainless steel, WITHOUT lubrification MAY cause seizing or galling problems.

Nut and bolt will be “welded” together, and exactly this was mentioned in Strida forums, corresponding to my own experience.

The possible solutions for the problem would be, in my opinion:

a. To change the bolt to stainless steel (application of anti-seizing compound ABSOLUTELY necessary)

b. To change the nut to the same steel specification as the bolt, not stainless (I would recommend application of anti-seizing compound although NOT necessary)

c. To change nothing, in this case a small amount of an anti-galling/seizing product applied on the bolt would solve the problem for a long time.

[Working with stainless steels like Nirosta, V2A and Inox for over 25 years I would strongly recommend the use of the product below:

neverseezproducts.com/antiseize.htm ]

The technicians of Ming cycle actually have no information about seizing or galling of stainless steel?

I do not know what sort of bolt and nut you use at fabrication of the Strida, but both of my Stridas were originally equipped with this material combination, as I got them in hand here in Austria.

I would like to post our correspondence in Strida forums, maybe some member is able to enhance communication.

With kind regards

BSA

![]() This time I replied, on 25.11.2010:

This time I replied, on 25.11.2010: