Hello Minkair,

Hello StridaSilver,

last week I’ve spoken with a bike-mechanic about the strength classes.

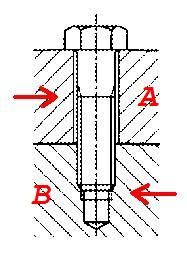

He said that Minkair’s explanation is absolutely correct, if you are looking at an “ordinary” screw connection.

(“Ordinary” means : Part B contains a thread, Part A a drill hole. By mounting the parts together will the bolt pass the hole.)

Appearing shear forces will take effect directly to the bolt.

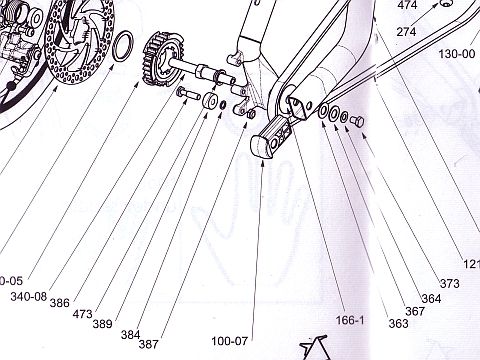

But, as you can see below, the special construction of the Strida rear joint (in conjunction with the rear wheel axle) cannot be seen as an “ordinary” bolt connection.

For the first, because the axle 340-08 wents completely through the bottom tube - any appearing shear or bending forces would be transferred to the axle, not to the bolt.

For second, please note that the big, second “washer” below the bolts head is actually not a simple washer. The big corrugated disc is a cup spring (disc spring, spring collar), which is strongly pressing the bottom and seat tubes together.

Regarding the construction details, we do not think that there will be any shear force applied to the bolt.

(Both of my Stridas are, against the drawing, equipped with one cup spring, therefore I don’t know the correct part number, 363 or 367)

Might it be possible that the pictured bolt connection is different from older Strida versions?

Dear Minkair, what do you think about it?

@StridaSilver

If you are unsure, fix the original bolt class, as Minkair suggested.

However, a 10.9 bolt is for sure a better choice than a bolt without class number (or 4.6).

Btw, does your Strida make clicking noises sometimes?

(like mentioned here: [url]Strida 5.0 "clicking" noise] )

Would be a good reason to change the bolts…

Both Stridas had these noises, by braking the sharp edges of the cup spring they were gone ![]()

The bolt will not break by carefully mounting or unmounting… ![]()

better quality here:

http://s769.photobucket.com/albums/xx331/Blackstridaaustria/bolt%20373/