@ carllracsr:

happy holidays, we’re looking forward for your pics ![]()

Just to mention it: A while ago,

@ Bietrume:

Yes right, I was also thinking of a fine pitch thread here, there is just the disadvantage of another unusual part - the fine threaded lock/adjusting nut(s).

However, I think such a kit cannot be realized without help from Ming (or their suppliers?)

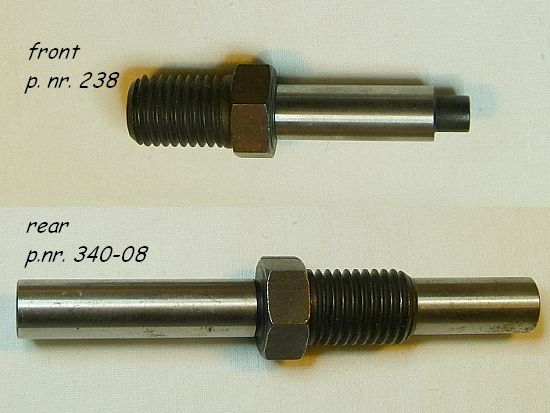

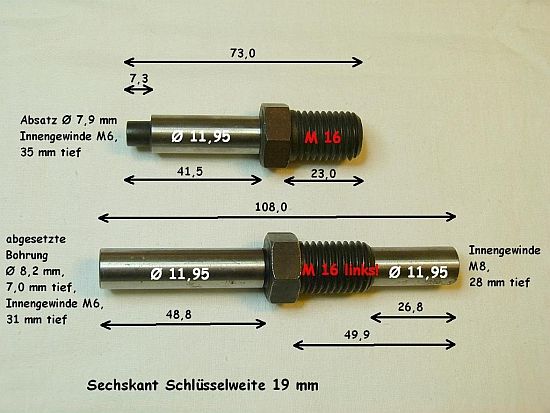

The initial reason to take the picture below was the request for a quote to create a pair of similar axles but made of Titanium.

It was sent to a German custom parts manufacturer (Al + Ti specialist), the guy told me that the inner threads will be problematic to drill - due to the Titanium characteristics.

He meant it would be much more easy to elongate the axles a bit and use outer (male) threads.

(Function would be recovered by the using nuts instead of bolts, of course will a magnet modification - or even redesign - be required.)

Anyway, the working costs for such a (yes, Titanium) custom axle pair would be ~ 300 €.

So, even if made of steel, the costs for the kit will be far above your limit, I’m afraid of…

(I did not consider the costs for the 100-07 part made of steel and the smaller parts).

Above will apply to most European countries, I believe…custom made parts in small amounts are very pricy.

With the help of Taiwan could the kit manufacturing costs be decreased dramatically:

Did you know that the shown original axles were bought for ~ 20 € - per pair?

End user price, including all the sub-dealer margins…

Below the correct position of the axles to each other ![]()