Hi Googleg,

welcome to Stridaforum!

I’m sorry to hear about your troubles, doing the same upgrade a few months ago I had no problem, but my Strida’s are 5.2, they seem to have a different snubber.

I guess your snubber looks like this:

http://picasaweb.google.co.uk/Human.Amp/StridaTech#

(Pictures by Human Amp)

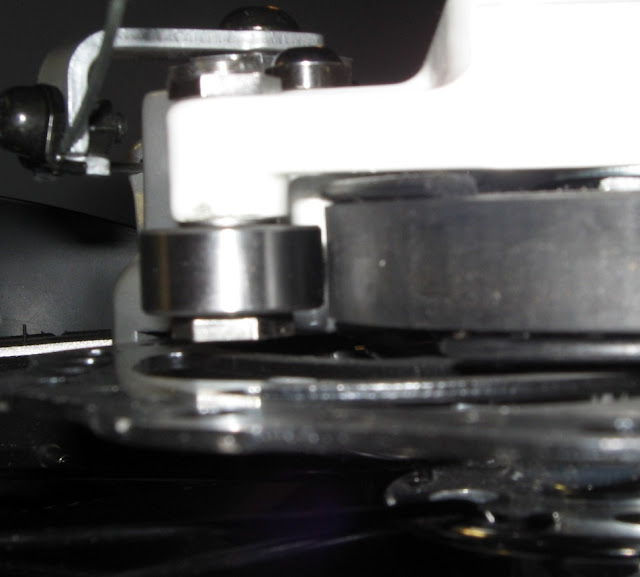

This is the 5.2 snubber:

Do you see the difference?

For my opinion the belt seems to be to loose.Adjusting belt tension? ]

At first , you have to loosen the big groove nut with the correct tool (doing this by a hammer and a drift punch might damage the groove nut), then you should be able to loose the tension bolt with a 6 mm Allen key ( you actually used a screwdriver ?).

Thanks for your pictures, I noticed something strange on them:

Here is some additional information from Hongkong Strida Club http://www.hkstrida.org/ :

strida.us strida.com web site for more info.

D) More FAQ’s

Snubbers

Best regards